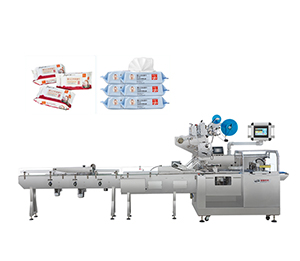

Machine real shot

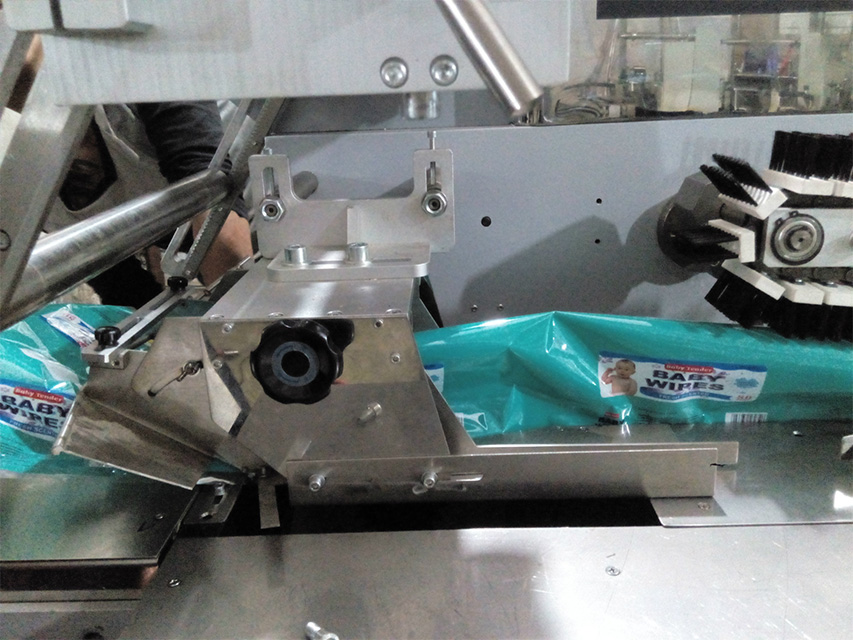

Customizable packaging connection

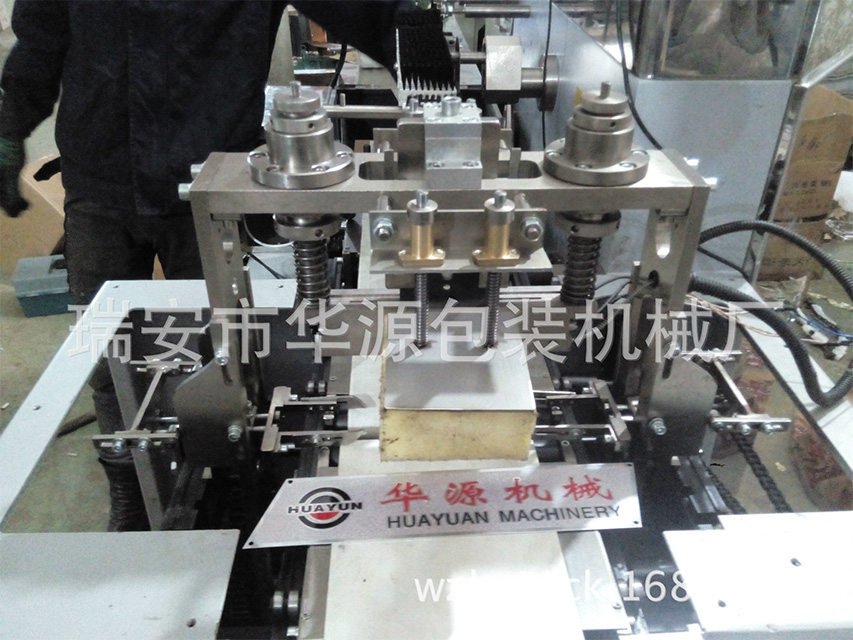

Internal structure

Workshop real shot

Packaging sample

Shipping package

Enterprise honor

|

1、 |

The length of the production product is directly set on the touch screen, which is simple and convenient. |

|

2、 |

Opening position and label position adjustment are directly operated on the touch screen, avoiding position changes caused by mechanical adjustment. |

|

3、 |

The whole machine adopts servo motor, which makes the machine run more stable, with lower noise, faster speed and higher precision. |

|

4、 |

The machine is equipped with a date printer to facilitate the customer to print the production date and batch number on the product. |

|

5、 |

Fixed bag making machine for easy adjustment. Equipped with a configurable bag maker for customers to change product specifications. |

|

6、 |

Equipped with a gusset device. |

|

7、 |

Work flow: packaging film, printing production date, opening mouth, sticking big label, sticking anti-tear label, pulling to conveyor, conveyor belt feeding, feeding and wrapping mechanism, middle sealing, pulling to conveying, horizontal sealing cutting, finished product delivery |

| Power |

380V 50HZ |

| Total power |

8KW |

| Production speed |

30~60 packs/min |

| Expanded size |

(180~300)×(90~120)×(30~80) mm (length × width × height) |

| Control system |

PLC control system, color package touch display |

| Applicable materials |

OPP/PE、PET/PE |

| Machine weight |

1900 kg |

| Machine size |

5280×1000×2100 mm (length×width×height) |

| Optional production |

anti-tear labeling device |