Introduction

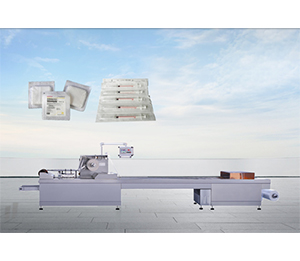

Packaging example

reliability

|

1、 |

Stable and reliable traction driven by servo motor |

|

2、 |

The center distance of each column is guaranteed: use a special machine tool to process four holes at the same time. |

|

3、 |

Pneumatic guarantee: adopt fixed-point production of cylinders and brand-name pneumatic parts. (See configuration list) |

|

4、 |

Electrical system guarantee: use brand-name electrical components. (See configuration list) |

|

5、 |

Production hygiene guarantee: Stainless steel and non-toxic PVC are used for the surface of stainless steel, and the contact surface with injection and medicine. |

Specifications and structure of each component

The principle and characteristics of each station mechanism of the equipment

|

1、 |

Preheating of the lower film: The heating plate is closely attached to the heating film, and the heating efficiency is high. The heating plate is automatically separated when it is towed. |

|

2、 |

PVC molding: the upper and lower molds are locked by cylinder action, and there are sealing rings to ensure no air leakage, and vacuum molding. Reliable molding. |

|

3、 |

Heat sealing: The cylinder moves to seal the upper and lower molds, and the upper mold is heated with a cylinder buffer. The upper and lower molds are sealed with anilox. Good airtightness. |

|

4、 |

Adjusting mechanism: each mold box mechanism can adjust the left and right positions on the machine base. It is convenient to adjust after changing the mold. |

|

5、 |

Mould positioning: positioning of the pressing plate, simple operation and convenient replacement. |

|

6、 |

Cutting section: shaftless cylinder cross cutting, easy to adjust the position. For hob creasing or slitting, the hob can be added or subtracted according to the section. |

|

7、 |

Printing device: Cylinder type letterpress printing, synchronous printing, which can save the cost of consumables. |

Product advantages

|

1、 |

The machine body is a casting, which absorbs vibration without deformation. The wall panels on both sides of the fuselage are made of No. 45 steel (thickness 16mm) with strong rigidity, thickness and stability; |

|

2、 |

The film chain is backward-leaning, and the opening and closing action can be controlled in place, in line with European and American standards; |

|

3、 |

For standard size products such as syringes, the upper mold of the forming and heat-sealing mold is replaced with a drawer-type extraction. There is no need to disassemble the mold frame, and the mold frame for different strokes does not need to be replaced. |

|

4、 |

The positioning design of the lower mold pin of the forming and heat sealing mold makes the replacement and positioning simple and quick to avoid the disadvantages of screw fixing. |

|

5、 |

The mold and cutter stations all have external handwheels for easy adjustment of positions, suitable for molds with different strokes. |

|

6、 |

The heating method adopts an aluminum heating plate with uniform pipe distribution and integral casting, which has uniform heating and long service life, avoiding the disadvantages of heating pipes. |

|

7、 |

The cross-cutting can be flexibly used serrated cutting or scalpel type, which is convenient for maintenance and adjustment. |

|

8、 |

The cursor alignment system adopts American Bonner, which is accurate and reliable. |

|

9、 |

The temperature control adopts Mitsubishi temperature module, which has high accuracy and can easily realize data export and connection to MES system. |

|

10、 |

The automatic feeding system of the syringe adopts a chain-plate timing belt to avoid the disadvantages of the screw scraping the printed content. |

|

Serial number |

project |

Technical Parameters |

| 1 |

working frequency |

6-10 times/min |

| 2 |

Production capacity |

600 molds/hour |

| 3 |

Forming area of each mold |

Standard: 365×365×70mm |

| 4 |

Standard: 365×365×70mm |

Standard 20-400mm |

| 5 |

Section specifications |

Common throat swabs 25×200mm, 16 pieces per row, double rows per mold, can be customized |

| 6 |

Packaging material |

Upper membrane 0.02-0.1×410mm (dialysis paper, soft membrane, etc.) Lower membrane 0.1-0.3×425mm (soft membrane, dura mater, etc.) The inner diameter of the membrane core: φ70-76, the outer diameter of the membrane roll: φ250mm |

| 7 |

Cursor registration or printing |

Error <0.2mm |

| 8 |

Heating power consumption |

Forming upper and lower heating: 6KW, heat sealing heating: 6KW |

| 9 |

Main motor |

Servo motor 1.5Kw |

| 10 |

Air source conditions |

Air flow rate per minute>0.2m3 (self-provided) Pressure: 0.4-0.6Mpa |

| 11 |

Vacuum condition |

Vacuum degree -0.09Mpa |

| 12 |

Mold cooling |

Water-cooling pipeline: consumption is 60L/h, water source and circulation are from standby. |

| 13 |

Standard machine dimensions |

6478×1150×1621.5(L×W×H) |

| 14 |

Length of feeding table |

Standard: 2045 mm. |

| 15 |

Total Weight |

1700kg |