|

|

|

Molding screw: all stainless steel, slow wire cutting, smooth and beautiful

|

Feeding roller: adopting triangular plane, misaligned feeding, easy to clean, no need to press, automatic material feeding

|

|

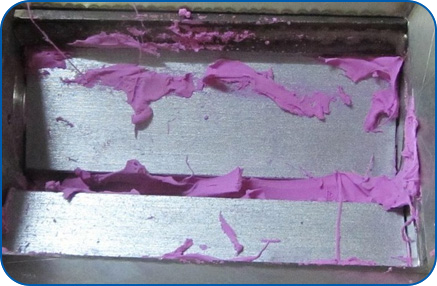

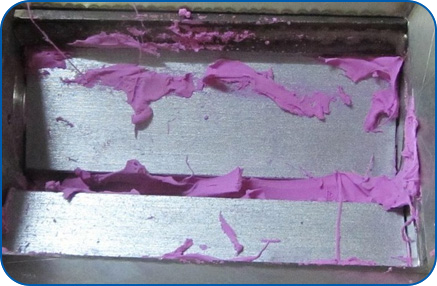

Forming Abrasives: Shaped Abrasives can be customized in a variety of shapes. Easy to replace. Also can be cut by machine.

|

Cutter: cold steel treatment, cutting knife, cutting, non-stick knife, smooth and beautiful

|

|

|

|

Cylinder: High-speed slitting package with high-speed cylinder or servo up to 160 bags per minute

|

Belt: Use beef tendon belt Single belt can be used for up to 1 year!

|

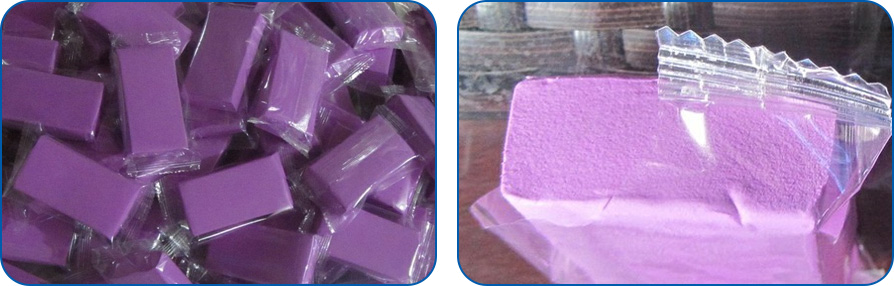

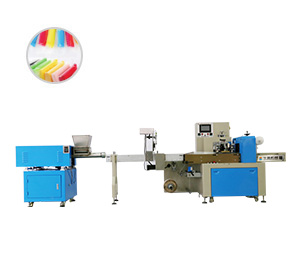

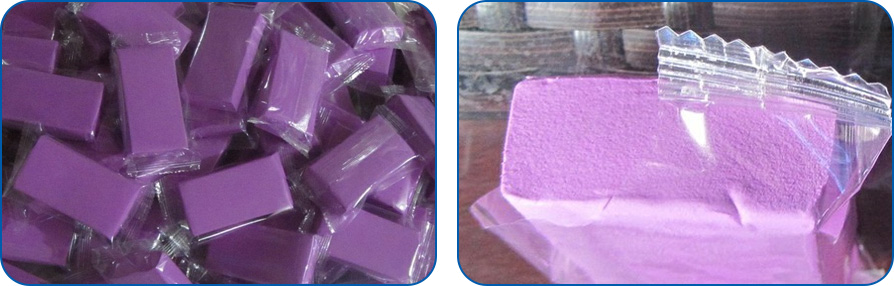

Packaging sample

This machine is made by extrusion molding and then automatic packaging and printing date. The whole process is automated. The packaging speed is fast, the finished product is beautiful, the labor cost is saved, etc. The first domestically used servo squeezing and slitting device can reach the measurement accuracy of about 1% gram. The high-cutting is crisp, and the open box structure is convenient and quick to clean. It is suitable for the light-cut ultra-light clay type. The cutting and packaging is the first to adopt the new servo cutting system. The packaging speed is fast to track and accurately solve the domestic light mud packaging waste packaging material packaging difficulty. Technical problems with slow operation speed. This machine is easy to operate and easy to use (can also be customized for various monochrome or multi-color molding and packaging production lines)

1. Machine size Length 5000mm*Width 1000mm* Height 1500mm

2. It is made by pressurizing the material in the extruder

3. A method of continuously molding through a die in a flowing state.

4. Motor: 220V, 50/60HZ 4.5kw (380V,)

5. Material: The material contact surface is stainless steel

6. Packing range: Fully automatic packaging for 5-50g materials. Packing 100g. Large-size extruder can be used.

7. Program control, convenient and simple, the length of the extruded mud can be controlled in the program. Can be tracked online with the packaging machine

8 extrusion system; mainly composed of screw and barrel, is a key part of the extruder, light mud through the extrusion system

9. Extruding a uniform fluid and, under the pressure established by this process, continuously and quantitatively pressurizing the extruder head by the screw

10. Light mud cutting machine drive system: drive the screw, so that the screw can obtain the torque and speed required in the working process, consisting of various sizes of gears, drive shafts, bearings and motors.

11. Traction device: its function is to uniformly pull the bobbin and control the cross-sectional dimension of the workpiece to make the extrusion process stable

12. Styling device: Its function is to stabilize the color mud extruded from the machine head according to the predetermined shape and to finish it, so as to obtain a more accurate cross-sectional shape, size and bright surface.

The control part of the light mud extruder adopts our advanced programmable controller. Its powerful control function and flexible modular structure can meet the control of various types of extrusion equipment, and can be combined with our packaging machine to form a color mud production line; Man-machine interface, large-screen color display, can conveniently monitor and operate the neat equipment; speed control part color frequency conversion speed control device, using superior vector control performance, can ensure the smooth and synchronous parts of the extrusion equipment .

First, the material is extruded smoothly, the cutting is dry, and the logistics barrel is stainless steel and never rusts.

Second, the fault alarm function can display the cause of the fault, the fault location

Third, light mud extruder, color horizontal single screw type, with the following characteristics

1) The heat generated by friction is small

2) The shear force received by the special material is relatively uniform

3) Large output capacity and stable extrusion

4) The barrel cleaning is convenient

Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units.

Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units. Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units.

Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units. Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units.

Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units. Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units.

Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units. Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units.

Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units.